Tracing Wool’s Intricate Journey from Fleece to Fabric

How does raw fleece become the yarn, fabric, and garments we love? On September 16, 2025, fiber farmers, producers, designers, mill owners, and wool enthusiasts gathered at Willow Creek Farm Preserve in Collegeville, PA, to find out.

Hosted by Pennsylvania Fibershed, in partnership with Willow Creek and the Pennsylvania Sheep and Wool Growers Association, the immersive afternoon walked participants through every step of the wool supply chain—right where it begins, with the sheep themselves.

Setting the Stage

The event, From Fleece to Fabric: A Wool Supply Workshop, was designed to provide tools, knowledge, and connections for a stronger fiber future. Over four hands-on hours, attendees saw and touched each step of the journey from raw fleece to finished textile. For many, it was an opportunity not just to learn technical skills, but to connect with others shaping Pennsylvania’s growing fiber economy.

Shearing, Skirting, and Fiber Evaluation

The day opened with a session on fleece assessment, highlighting how the earliest decisions (made just minutes after shearing) determine fiber quality and marketability. Participants learned to spot breed-specific characteristics, recognize faults, and understand how preparation choices ripple through the rest of the supply chain.

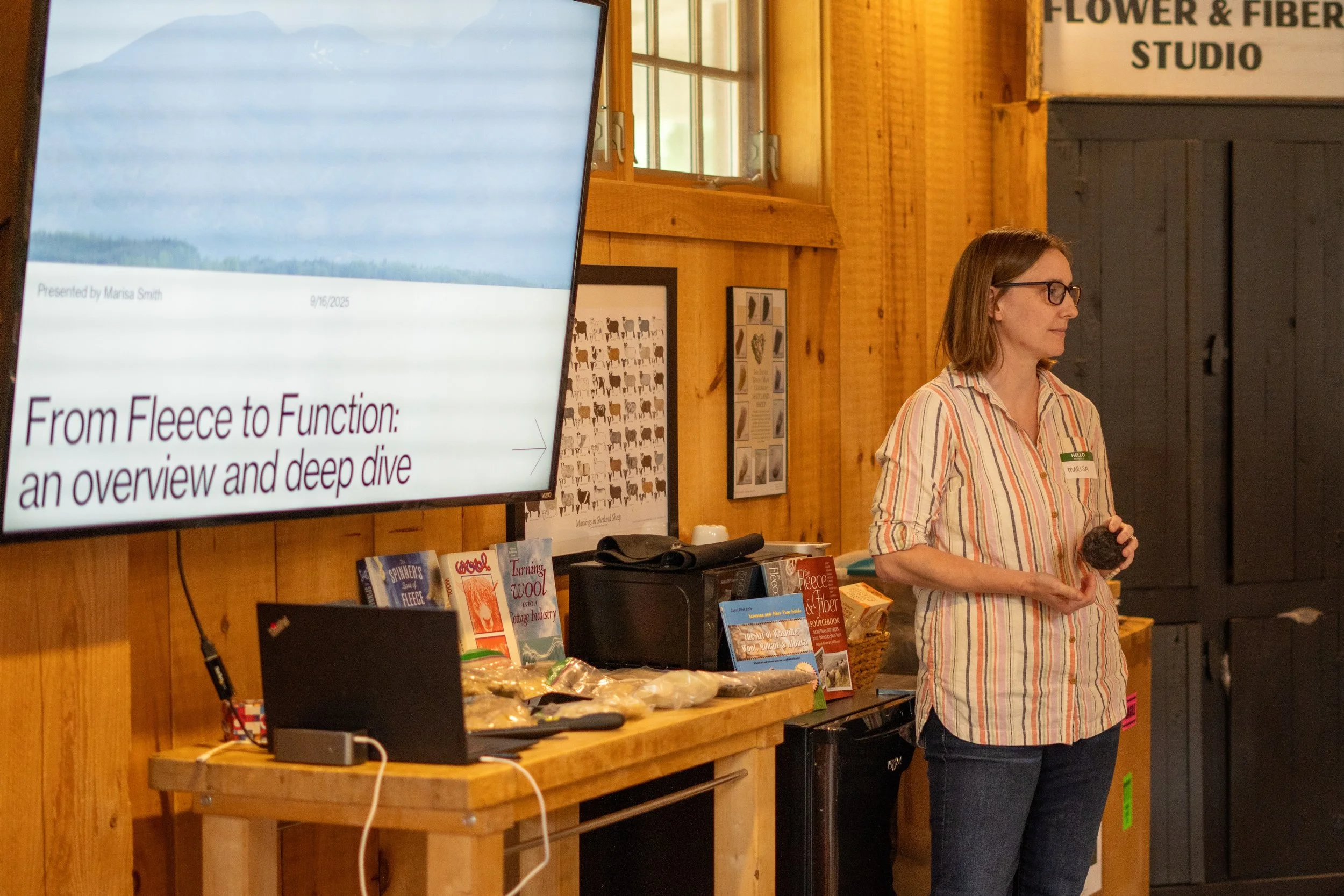

Marisa Smith, the workshop leader and fiber educator, emphasized that “every fleece has a purpose.” Even wool that doesn’t meet traditional standards can find a use—whether for felting, insulation, or niche artisan products. The key is knowing how to handle, sort, and market it.

Marisa also outlined best practices for shearing preparation, from understanding your breed and keeping sheep dry, to planning for inclement weather and recording animal production and fiber type.

Inside the Mill

Next came one of the day’s most anticipated experiences: a tour of Willow Creek’s onsite Belfast Mini Mill. Guided by farm co-owner Melissa Smith, attendees explored how raw fleece is transformed into batts, roving, and yarn under the farm’s Born, Shorn, Milled & Spun ideology. Melissa shared practical advice for farmers hoping to maximize their returns when sending wool to a mill—tips on cleanliness, expectations in wool volume loss in the production process, and communicating with mill operators to ensure the best possible processed fiber comes back.

Voices from Across the Supply Chain

The afternoon also featured a dynamic panel discussion, featuring expert voices spanning the fiber industry:

Leah D’Ambrosio, founder of sustainable knitwear brand Wol Hide, spoke about the power of transparent supply chains and designing with intention. By sharing the same alpaca fashions from different seasons, she illustrated how animal care and fiber processing directly shape the finished product.

Joel Cohen, of Artex Knitting Mills in New Jersey, shared insights from a family business and discussed his experience in working directly with customers, carefully illustrating the difference between the retail and wholesale markets.

Mattie Horchler, a livestock educator and sheep breeder, served as moderator and highlighted how animal care and genetics shape fiber quality.

Marisa Smith, continued to discuss how important it is for producers to have an end goal for their fiber throughout the process.

Melissa Smith, both shepherdess and mill owner, explained how her on-site mini mill is key to managing operations and maintaining wool quality.

In the end, the message was clear: farmers have more options than they may realize. Working directly with knitting mills opens the door to finished products without requiring design expertise. At the same time, if the goal is to collaborate with designers, producers should keep in mind that consistency matters. Clear communication about flock changes—like adding new sheep or shifting breeds—helps build trust and ensures designers can plan around the natural variability of fiber.

Wool Grading in Action

Back outside, Marisa Smith led a wool grading session, where participants learned how to evaluate their fleeces for different end uses. From fine, soft wool suited to next-to-skin wear to coarser fibers better for outerwear or rugs, and even wool pellets, attendees discovered how grading informs marketing decisions and pricing. The hands-on demonstration gave producers confidence to assign value to their own clips.

Building a Stronger Fiber Future

As the sun dipped lower over Willow Creek’s pastures, conversations buzzed with possibility: collaborations between farmers and designers, new markets for undervalued wool, and the shared goal of strengthening Pennsylvania’s fiber economy.

The event closed with a reminder of PA Fibershed’s mission: to create a sustainable, equitable, and circular textile future grounded in local resources and community connections. For those who came seeking knowledge, they left with not only practical skills but also new relationships—and a deeper sense of belonging to a movement larger than themselves.

Photos by Aqsa Rizvi